Reducing value, rushing time to market, and enhancing overall finish-person expertise are three essential goals that each good product growth agency aims to accomplish – and rapid prototyping applied sciences may help them achieve this.

In the case of product growth, there are several steps to the method: idea, design and engineering. Following this, the idea is bodily dropped at life by the prototyping stage (to test for kind, fit and perform) prior to coming into the final stage of development – manufacturing.

Key to any product growth process, however, is quick time to market – and that’s the place rapid prototyping comes into play. Specifically, rapid prototyping is defined as a gaggle of technologies that make the most of data from a pc-aided design (CAD) file to shortly fabricate a bodily product. Compared to typical prototyping technologies, rapid prototyping creates components in a lot faster timeframes and at cheaper prices, saving companies time and money.

The concept of rapid prototyping took place within the 1980s when the “machine tool crisis” hit, a period where America not led the way in machine instruments and machine software manufacturing. In consequence, product builders began taking a look at other methods to create models and prototype elements. Like most technologies in the early levels, there were growing pains with the rapid prototyping initiative. Today, nevertheless, rapid prototyping expertise has superior to the point where it isn’t used just for prototyping functions, however for short-run manufacturing in quite a lot of industries as nicely.

Methods/Techniques

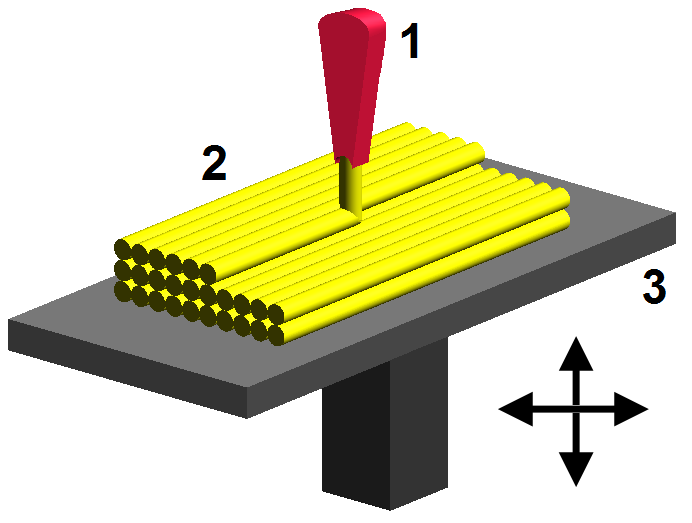

The phrases “rapid prototyping” and “additive manufacturing” are synonymous. Unlike subtractive manufacturing strategies, which contain chopping away material to create a part, additive manufacturing consists of building the half from the bottom up, using only the material mandatory. Essentially, additive techniques “grow” the half, and it’s each fast and inexpensive for prototyping compared to various methods.

Rapid prototyping largely bought its begin in the automotive business as a method for designers and engineers to check ideas as well as elements for kind, fit and operate in new vehicles. However, rapid prototyping is used right this moment in nearly any product development state of affairs, from automotive to aerospace to consumer products to even the medical industry.

Architects are using the rapid prototyping expertise 3D printing to showcase residential and industrial improvement before it goes to construction – as was the case lately in Detroit, Michigan, the place plans transfer forward to create a downtown district in its Midtown neighborhood, consisting of residential and industrial properties, as well as a brand new sports activities stadium. In aerospace, Bell Helicopter used rapid prototyping technologies to develop check elements of wiring conduits for its Osprey chopper. Within the automotive subject, automakers have taken to 3D printing automobiles to showcase at varied auto exhibits and different trade events.

The expertise is getting used to create solar panels, too. It’s even being utilized in outer area and in educational settings. Rapid prototyping isn’t only for prototyping purposes anymore, and is being used increasingly for brief-run manufacturing. A great example of that is in the medical industry, the place medical doctors are turning to 3D printing for making prosthetic limbs and implants.

Rapid prototyping is just not misplaced on hobbyists and entrepreneurs, especially entrepreneurs who are making an attempt to realize assist for a brand new product concept or innovation. With restricted funds available at startup, they’re turning to this extra inexpensive technology to create physical check elements that they will showcase – whether by way of a Kickstarter campaign or some sort of crowdfunding site – to gain assist.

Benefits/Advantages of Rapid Prototyping

Finance is one among the massive drivers of rapid prototyping know-how when compared to other varieties of prototyping applied sciences: it’s cheap. This is largely as a result of velocity of the process – and as everyone knows, time equals money.

Relating to rapid prototyping and 3D printing, the tooling is basically the CAD file that the equipment is programmed to create. Hence, there’s no expensive upfront tooling costs to pony up and there’s no doubtlessly excessive re-tooling costs to have to satisfy if the prototype isn’t as much as snuff – just a pc file to regulate accordingly. Therefore, course of cycle occasions aren’t delayed at all.

One in all the preferred subtractive prototyping technologies is CNC machining. While tooling isn’t required for this, and CNC machining is viable for some purposes, there are a number of key differentiators between this and rapid prototyping, notably its inability to produce a number of the more complicated shapes that rapid prototyping applied sciences can create.

Pros and Cons of 3D Printing

Rapid prototyping consists of additive applied sciences that rapidly fabricate a product. The most common rapid prototyping technology is usually known as 3D printing. There are numerous subcategories of 3D printing – reminiscent of SLS (selective laser sintering) and SLA (stereolithography) – but while these strategies differ, they all share the same common advantages. Here’s a have a look at some benefits of 3D printing expertise:

No tooling: Because tooling doesn’t need to be created, there are large value savings.

Complexity: Parts might be made via 3D printing to be extremely correct and even hollow.

Fast: Parts might be fabricated in hours, not days. In consequence, designers usually order or build a number of variations of the prototype part without delay to see which mannequin works finest within the intended utility.

Flexible: While 3D printing is most synonymous with creating plastic parts, the know-how has been tailored to help a wide range of different materials as nicely, such as metals.

Economies of scale: Additive manufacturing technologies can produce a small variety of elements at very reasonable value points. If you enjoyed this write-up and you would such as to receive more information concerning rapid prototyping service kindly see the web-page. Conversely, in the case of typical molding, a mold first must be bought to conduct part runs, which requires more of an upfront funding.

Easy: While the machines are still pretty expensive, it’s not an advanced piece of tools to be taught.

No know-how is perfect, and 3D printing has some drawbacks. Here’s a look at a number of the technology’s shortcomings:

Maturity: It’s not as mature as subtractive technologies, reminiscent of CNC machining.

Size limitations: Presently, the parts fabricated via 3D printing are limited by the scale of the 3D printer. Most of those machines are small and have restricted construct chambers for fabricating parts. Larger components and Rapid Prototyping Service merchandise have been made utilizing 3D printing, however the technology thus far is generally associated with creating smaller components and parts.

Materials: Arguably, materials are the biggest disadvantage to additive manufacturing know-how. For instance, most supplies aren’t manufacturing grade, but somewhat a similar version of the real factor. This limits some of their practical testing when compared to CNC machining, as an illustration, which can be utilized for useful testing and works with a whole lot of supplies.

SLA vs. SLS

As beforehand mentioned, two major sub categories of 3D printing contain SLA rapid prototyping and SLS rapid prototyping. SLA is an additive technology that uses a UV laser to cure resin, thereby building components layer by layer. SLS uses a laser to sinter powdered material in creating a totally functional prototype. (Two subcategories of SLS are DMLS (direct metallic laser sintering) and SLM (selective laser melting).

While SLS and SLA every are able to fabricate a prototype, they differ in their 3D rapid prototyping methods. As an illustration:

SLA elements are usually cheaper to construct based mostly on the method.

SLS is able to fabricate elements in a nylon material, which is hard but versatile.

SLA components typically have a smoother surface end than SLS components.

SLS parts are typically extra durable than SLA parts.

SLA components are better for show items, not essentially to test for operate.

Parts created by way of SLA are generally extra correct.

Rapid Prototyping Services

While rapid prototyping machines have become extra compact and extra reasonably priced through the years, a great piece of equipment is still expensive. That’s why many product improvement corporations are extra apt to outsource prototyping than carry it in-home. By uploading their CAD information to a qualified rapid prototyping service, they’re placing their product in the palms of experts. These specialists may help identify any product flaws in the CAD file and then work with product developers to appropriate it. Furthermore, the turnaround time with rapid prototyping companies is often very fast.

_MCU.jpg)