Rapid prototyping is the automated development of physical objects utilizing additive manufacturing know-how. To be taught more about rapid prototype prototyping, herunder I elaborate a 5 steps process to create a rapid prototyping model

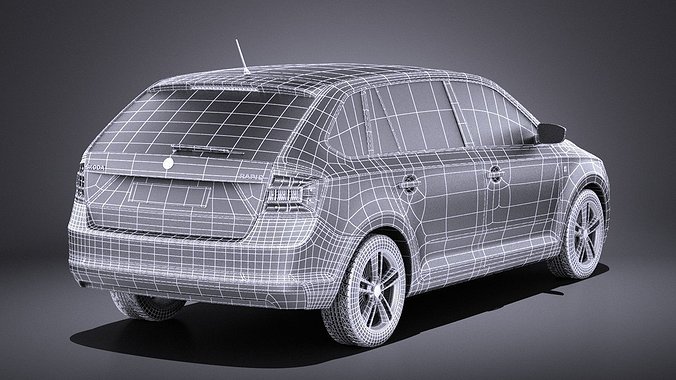

1. A 3D Computer aided mannequin (CAD) of the initial idea or idea sketch design shall be created.

If you loved this information and you would love to receive details concerning rapid prototyping price kindly visit the site. 2. This 3D CAD model will be transformed in a STL or IGES format.

3. The STL model will likely be sliced into thin cross-sectional layers.

4. The mannequin will probably be constructed one later atop another.

5. The model can be finished and cleaned: rapid prototyping your rapid prototype is prepared!

CAD Model Creation: First, the article to be built is modeled utilizing a computer-Aided Design (CAD) software program bundle. Solid modelers, akin to Pro/ENGNEER, are inclined to symbolize 3-D objects more precisely than wire-body modelers equivalent to AutoCAD, and will therefore yield better results. The designer can use a pre-present CAD file or could wish to create one expressly for prototyping purposes. This course of is equivalent for all the RP build techniques.

Conversion to STL Format: The varied CAD packages use a quantity of different algorithms to signify solid objects. To establish consistency, the STL (stereolithography, the primary RP approach) format has been adopted as the standard of the rapid prototyping business. The second step, subsequently, is to transform the CAD file into STL format. This format represents a three-dimensional surface as an meeting of planar triangles, “like the sides of a lower jewel.” 6 The file incorporates the coordinates of the vertices and the course of the outward normal of every triangle. Because STL recordsdata use planar elements, they can’t represent curved surfaces exactly. Increasing the number of triangles improves the approximation, but at the price of larger file size. Large, difficult information require more time to pre-course of and build, so the designer must balance accuracy with manageablility to produce a helpful STL file. Because the .stl format is universal, this course of is an identical for the entire RP build strategies.

Slice the STL File: Within the third step, a pre-processing program prepares the STL file to be built. Several programs are available, and most enable the person to adjust the dimensions, location and orientation of the mannequin. Build orientation is vital for several causes. First, properties of speedy prototypes vary from one coordinate course to another. For instance, prototypes are normally weaker and less correct in the z (vertical) direction than within the x-y plane. In addition, half orientation partially determines the amount of time required to build the mannequin. Placing the shortest dimension in the z path reduces the number of layers, thereby shortening build time. The pre-processing software slices the STL mannequin into various layers from 0.01 mm to 0.7 mm thick, depending on the construct approach. This system may also generate an auxiliary structure to help the mannequin during the build. Supports are useful for delicate features corresponding to overhangs, internal cavities, and thin-walled sections. Each PR machine producer provides their own proprietary pre-processing software program.

Layer by Layer Construction: The fourth step is the actual building of the half. Using considered one of a number of techniques (described in the following section) RP machines build one layer at a time from polymers, paper, or powdered metallic. Most machines are pretty autonomous, Rapid Prototyping price needing little human intervention.

Clean and Finish: The final step is put up-processing. This involves eradicating the prototype from the machine and detaching any supports. Some photosensitive supplies have to be totally cured before use. Prototypes may additionally require minor cleansing and surface treatment. Sanding, sealing, and/or painting the mannequin will enhance its appearance and durability.